| |

Development of PC-based control -- 1985 |

Member of Fortune 500

Until 1981, Flowcon was owned

by Berwind Instruments, to give an otherwise drab corporate report on rail car

manufacturing a high tech look.

The inability to stamp

out custom systems like cookies eventually "lost its luster" so they sold off

Flowcon to its current ownership. |

|

|

The Idea for a PC Based System - Radio Shack

In the early '80s, Radio Shack

asked Flowcon if we could control their new Conveyor

System in Ft. Worth, TX using their

computers. We agreed, and from that experience, we initiated PC-based batch control

systems to replace our dedicated "model 2200" systems. |

Standardized Processing

The challenge was to use the PC to do

things it was not normally suited to do.

| Real Time Control: we solved this by

creating our own execution kernel that switches tasks on a timed interrupt. |

| Communicate with relays and serial devices. |

|

|

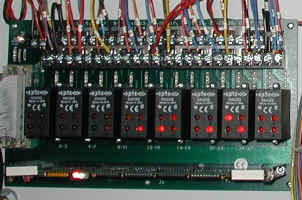

Modular

| The enclosure provides a wireway, barrier

strips for attaching wires, removable brain board, fused relays, and optically isolated

signals. |

|

|

A Five Scale Application

| All scales weigh simultanously and can be

sized differently, for optimal accuracy and speed |

|

|

Custom Processes

| Typical of a feed-mill, this computer

directed hand-add station prompts and verifys every operator addition. |

|

|

|